How to extract value from Training within Industry & Lean programs

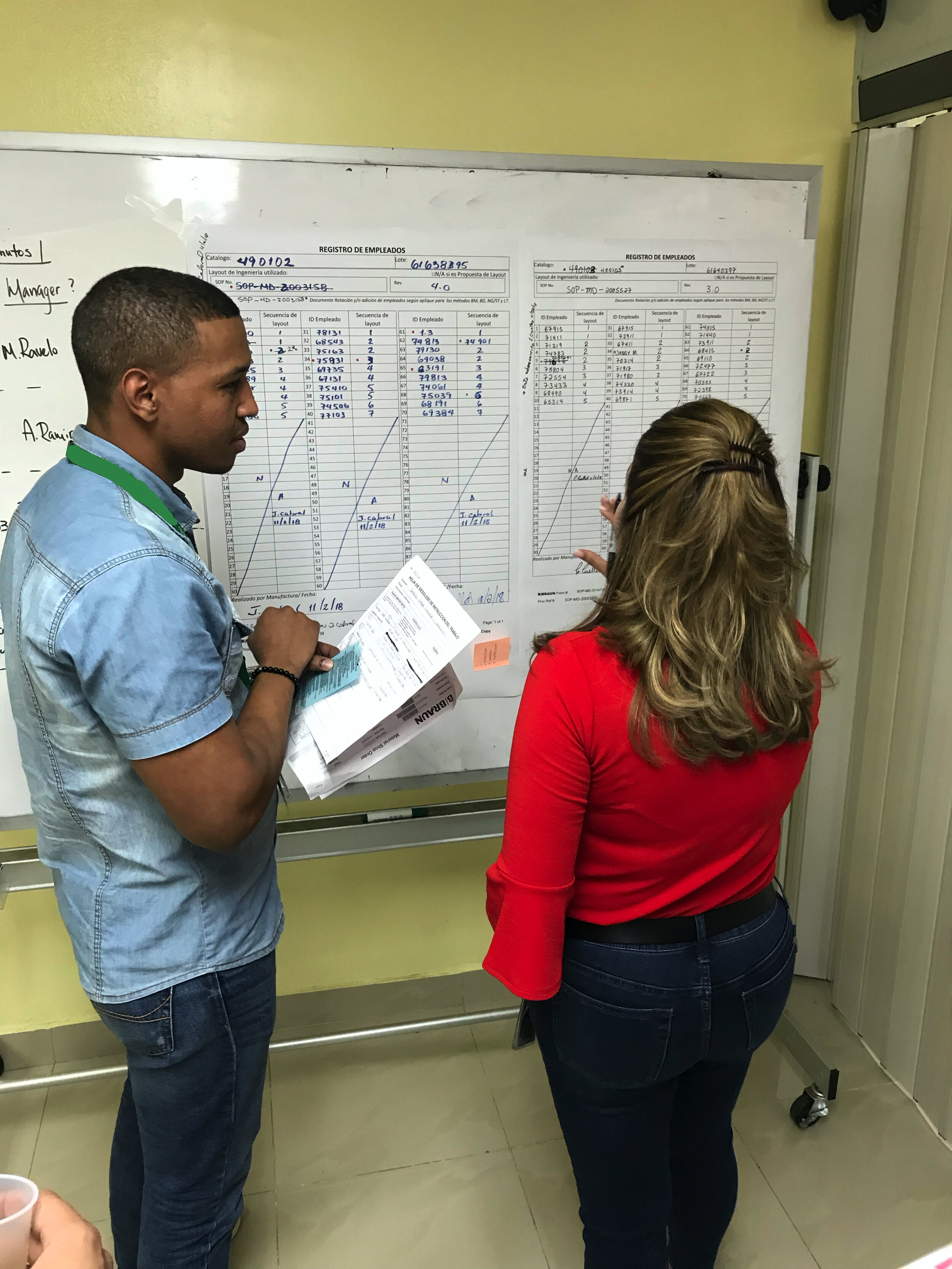

Extracting the value from Lean training or transformation program, including Training within Industry skills, requires more than just training. If we want to achieve acceleration of process improvement - in fact any successful organisational change - requires a change in the way we lead and manage others.

“Whenever we want change to happen,

the way we manage needs to change first.”

Companies that are doing a good job in introducing and using Training within Industry, Lean skills or Six Sigma skills can expect tremendous benefits. Not all are successful, however. Management skills and habits are one of the primary success factors. Companies with active management involvement tend to do much better. To make our people grow, we ourselves need to grow. Business results are determined by our skill in leading, developing and supporting our people and teams.

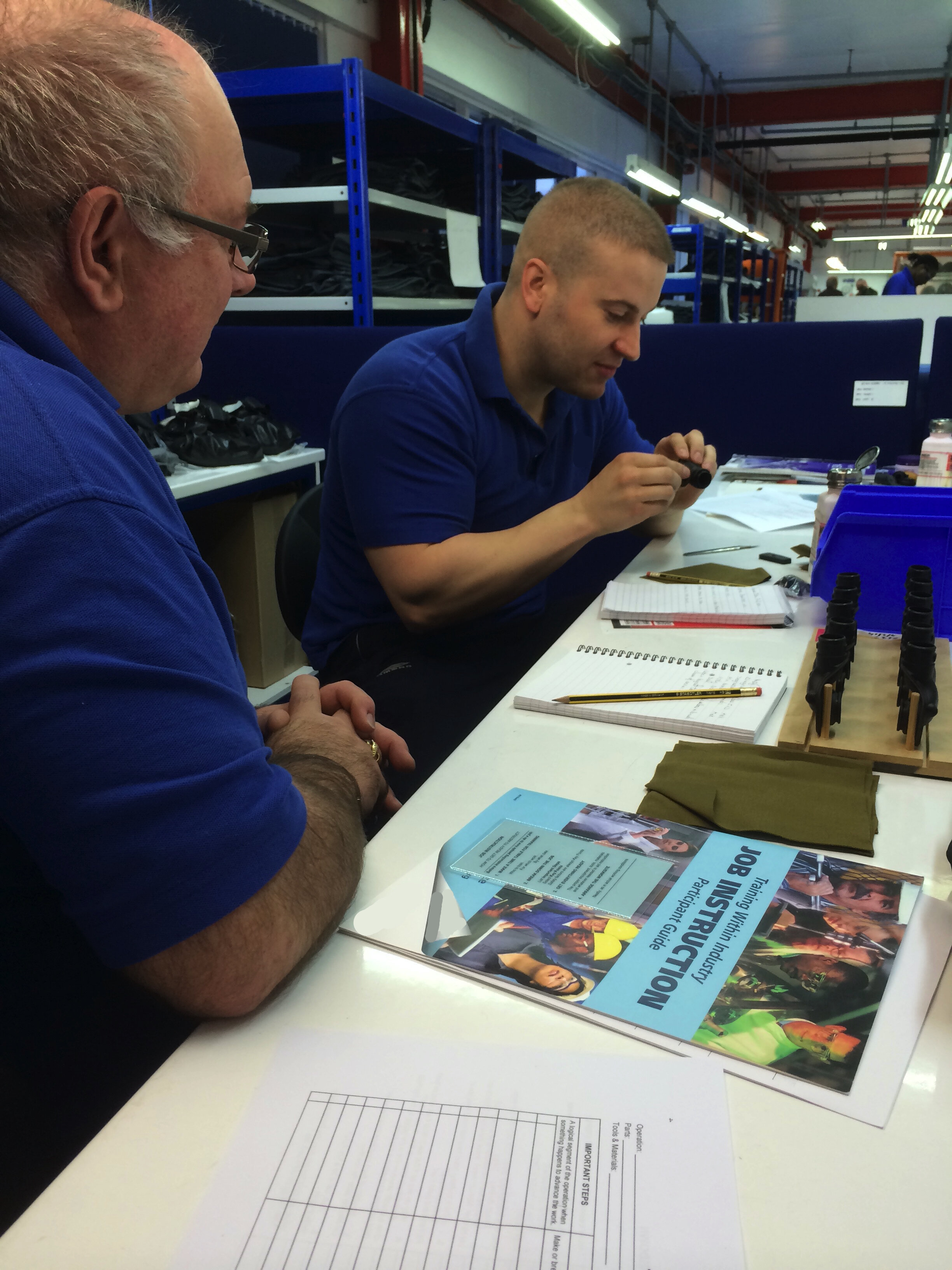

Critical manager skills for a successful Lean transformation include the ability to set clear direction, to train, coach, challenge and motivate people, and the ability to detect and correct process and systems problems quickly and sustainably. Managers also need to understand enough about the technical aspects of Lean, Training within Industry and Six Sigma to know what is possible and challenge their people. Attending the 10 hour foundation classes of Training within Industry or Lean Six Sigma with their supervisors and operators, should be a must for any executive serious about extracting a good return on the training investment.

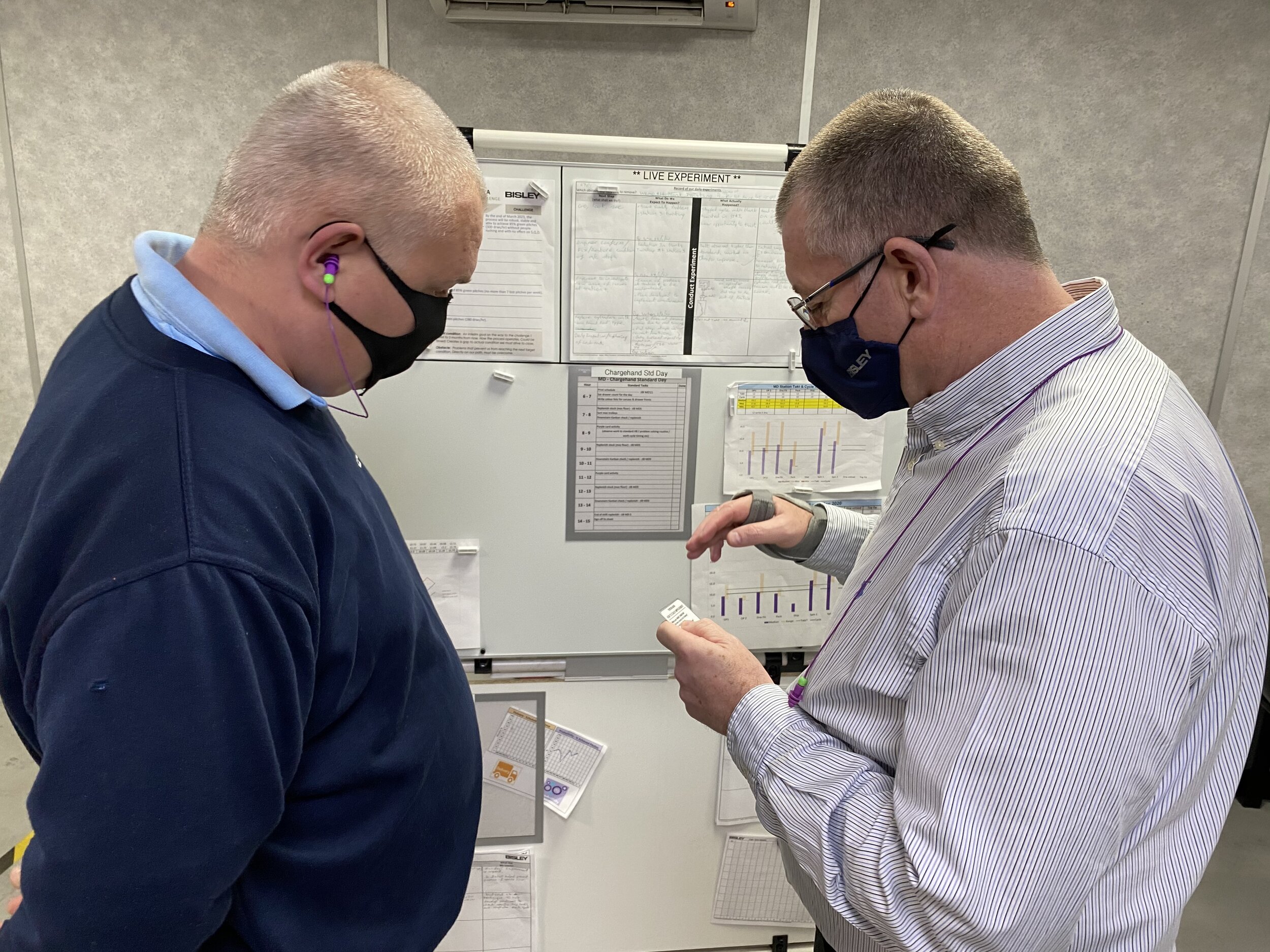

“You can tell what managers value by how they spend their time.”

Skills grow and deliver results when they are practised often enough. Changing our management habits is a critical element of successful transformations. Managers are the tip of the spear when it comes to driving rapid, effective change. What they say or don’t say, what they do or don’t do, what they do or don’t pay attention to matters - a lot! Company culture is the culture of its managers. Therefore, one of the best investments managers can do is in themselves: our Leader Standard Work training and Toyota Kata training are an excellent starting point.