The four-step method of TWI Job Relations (TWI JR)

Participants in TWI Job Relations (TWI JR) leadership training learn how to prevent people-problems by making the Four Foundations for Good Relations part of their daily work. Supervisors practising the four foundations of TWI JR habitually give quality feedback and guidance, show appreciation for good performance, involve team members in shaping upcoming changes, and actively support the development of skills and job roles. By doing this, they prevent many people problems. When they do arise, however, supervisors need to be skilled in detecting problems early and solving them swiftly, fairly and sustainably. This is achieved by applying the four problem-solving steps of TWI Job Relations.

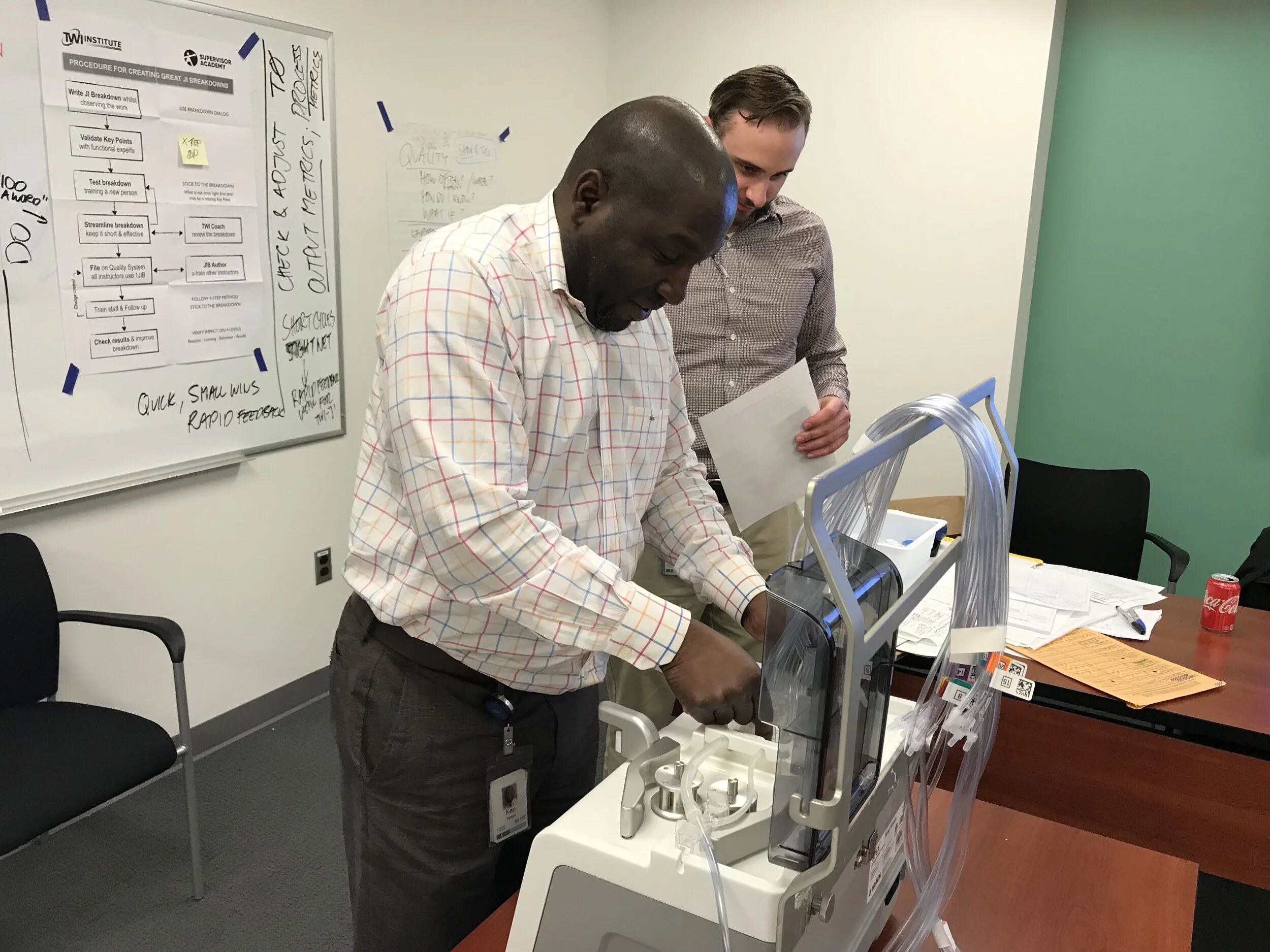

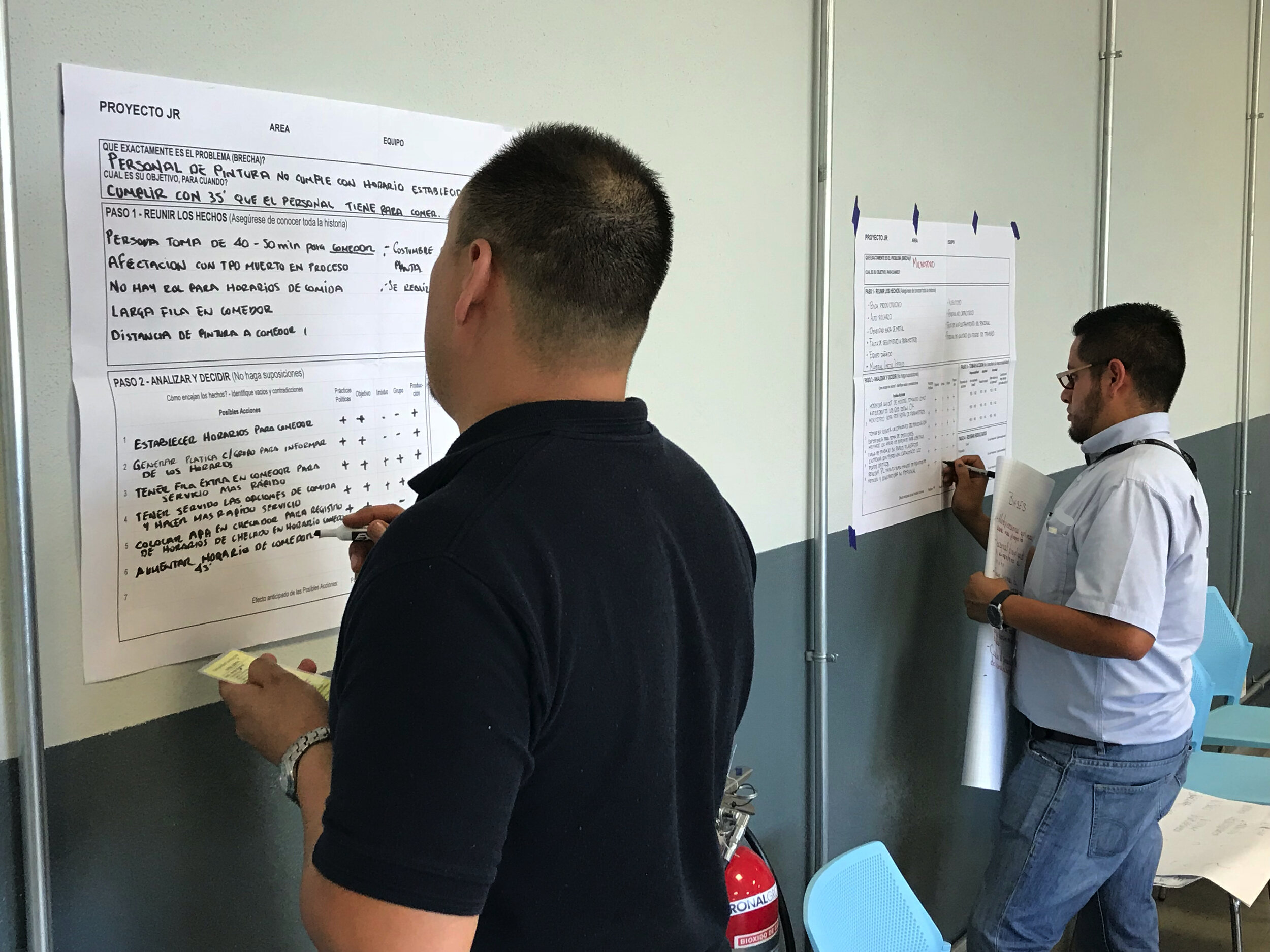

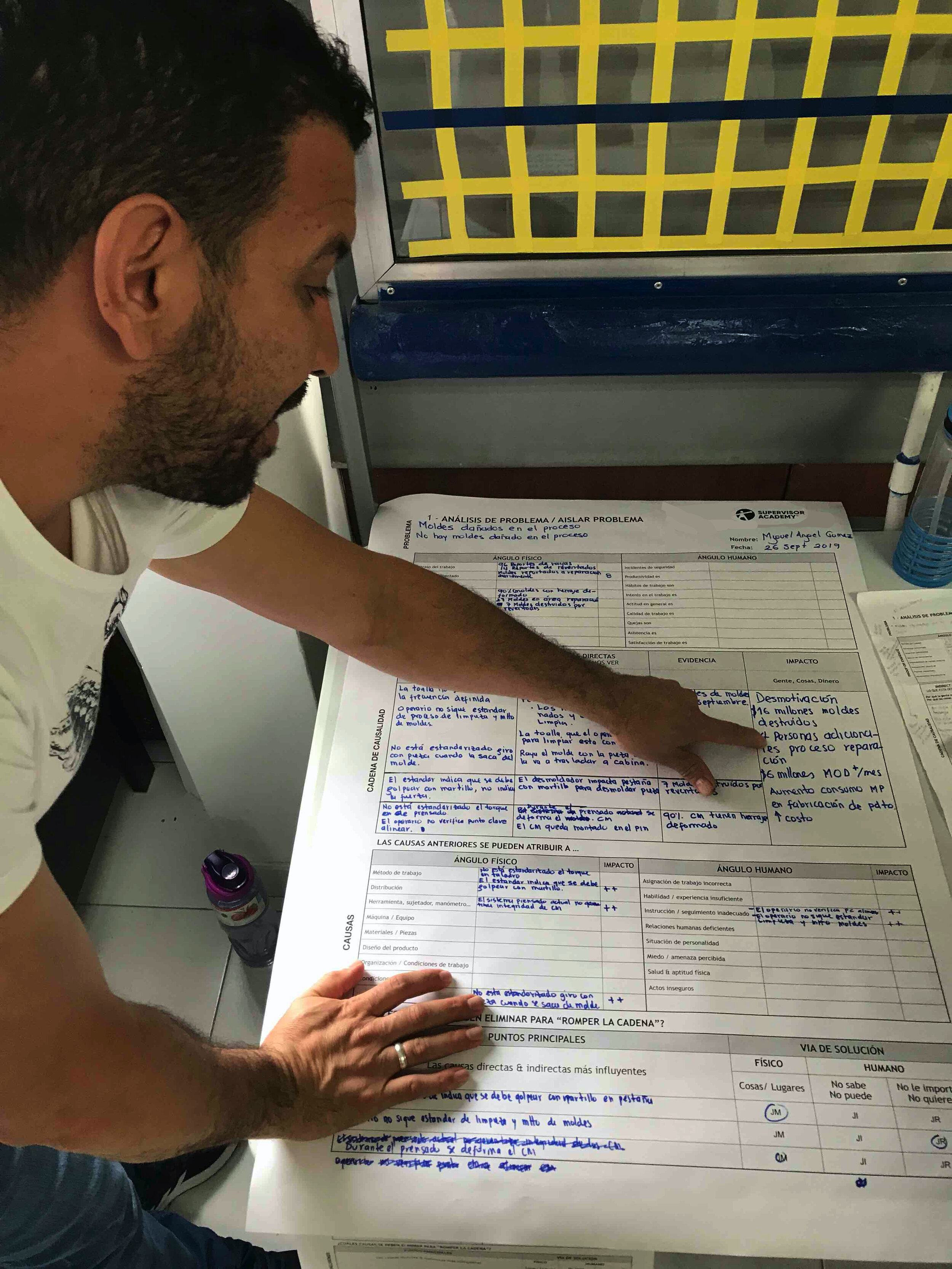

Step 1 - Get the Facts

In the first step of TWI JR the supervisor gathers all the facts related to the problem. By looking at what is known or recorded about the involved individuals (including written information about performance, attendance, achievements, disciplinary reports) as well as applicable rules and customs, the supervisor sets out to build a balanced picture of the problem. This data helps the supervisor to understand the problem context and evolution: did it start a long time ago, is it repetitive or a one-time occurrence? However, supervisors practising TWI Job Relations know that decisions should not be based on this kind of data alone. Before taking any decisions, it is critical to gather the opinions and feelings of the concerned individuals.

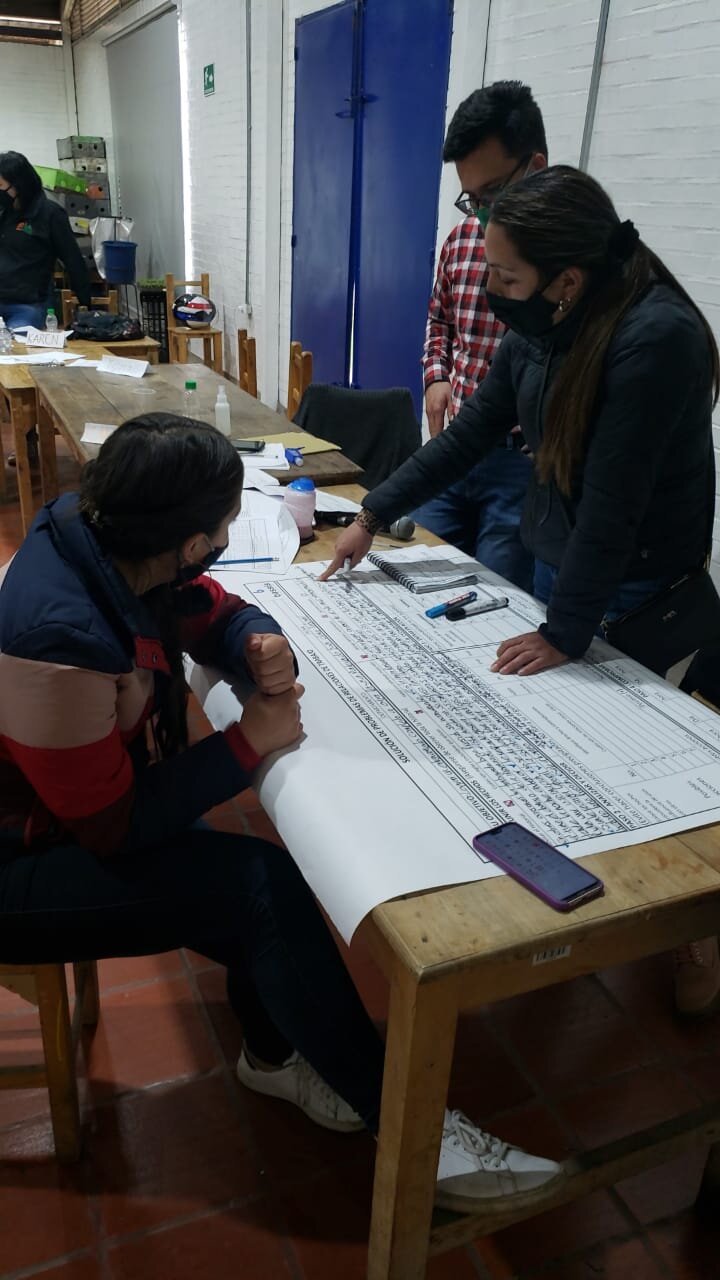

Step 2 - Weigh & Decide

In Step 2 of TWI JR the supervisor combines the facts into information that allows him or her to generate a diverse list of appropriate possible actions in line with company practices and policies. The supervisor then assesses the likely impact of each possible action by considering the effect of these actions on the supervisor’s objective, the individuals concerned, their team and the department’s performance. Particular attention is paid to including all of the facts available when generating possible actions, as this prevents the supervisor from ‘jumping to conclusions’ and taking inappropriate action. Based on this analysis, the supervisor decides which actions are likely to give the best result in Step 3 of TWI Job Relations.

Step 3 - Take Action

In Step 3 of TWI JR the supervisor takes a well considered action. The supervisor takes a final decision on what action s/he will take to solve the problem. She carefully considers her ability to handle the problem by herself or whether she requires assistance by a specialist experienced in handling this kind of personnel issues, colleagues of the individuals concerned, or whether she needs help in handling the problem consistent with relevant practices and policies. If the problem or action exceeds the authority of the supervisor, she refers it to her manager. Finally, before proceeding, the supervisor considers the timing of the action. The right action at the wrong time could have a negative effect on the department’s people or performance.

Step 4 - Check Results

In Step 4 of TWI Job Relations the supervisor follows up on the actions and their effect on output, attitudes and relationships in the department. Here again, timing is a key consideration, as the supervisor plans how soon and how frequently to follow up. Small adjustments or additional actions might be needed to fully solve the problem. Supervisors practising TWI JR know that when dealing with people-problems one cannot rely just on figures but must be attentive to subtle changes in people’s behaviours to know if the action is working.