TWI Problem Solving

Use TWI Problem Solving skills to develop your front-line leaders’ capability in identifying and removing the true causes of complex production problems quickly and sustainably.

TWI Problem Solving (TWI-PS) enables organisations to raise people and process performance to the next level. It allows middle-managers and supervisors to leverage & enhance the benefits of standard work established through TWI Job Instruction.

TWI PS creates predictable, reliable performance through effective process stabilisation, and boosts performance though the development of simpler, more reliable processes & methods.

WHAT PROBLEM SOLVING SKILLS DO SUPERVISORS NEED?

The ability to problem-solve rapidly and effectively is part of the essential skill-set of high performing supervisors. Problem solving requires supervisors to be able to work effectively at two levels: containment (short term, ‘stop the bleeding’) and countermeasure (longer-term, remove the cause, prevent recurrence).

At the first level “containment” supervisors must be able to quickly identify and enact measures that stop poor quality, keep production moving and people conflicts from escalating - and return to the normal, stable operating pattern defined in standard work methods. This skill is developed in our Leader Standard Work training program.

At the second level “countermeasure”, supervisors and middle managers dig deeper into the problem, understand its causes and develop longer-term solutions that prevent its recurrence and raise performance. This skill is developed through our TWI Problem Solving training program.

HOW DOES TWI PROBLEM SOLVING WORK?

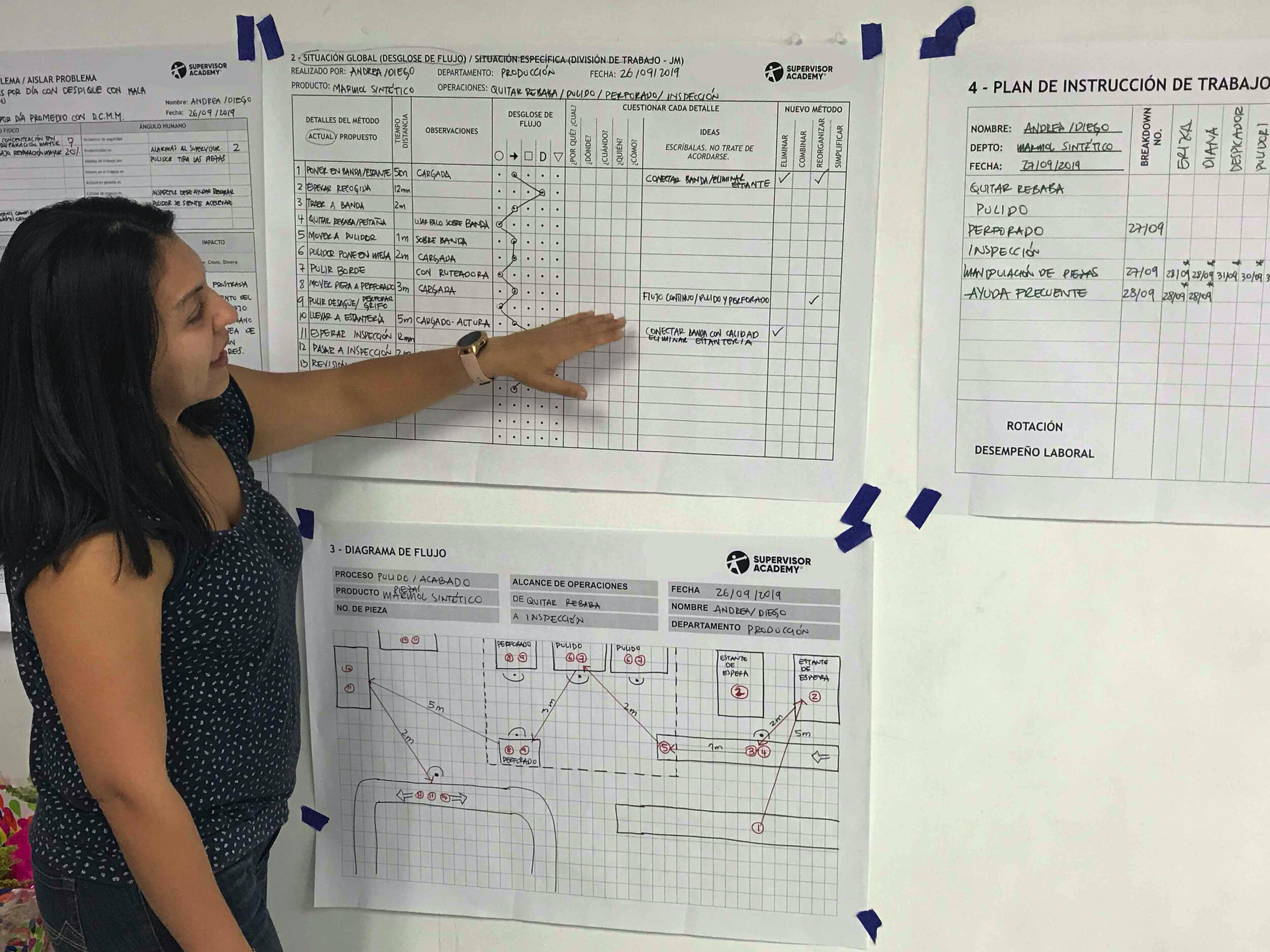

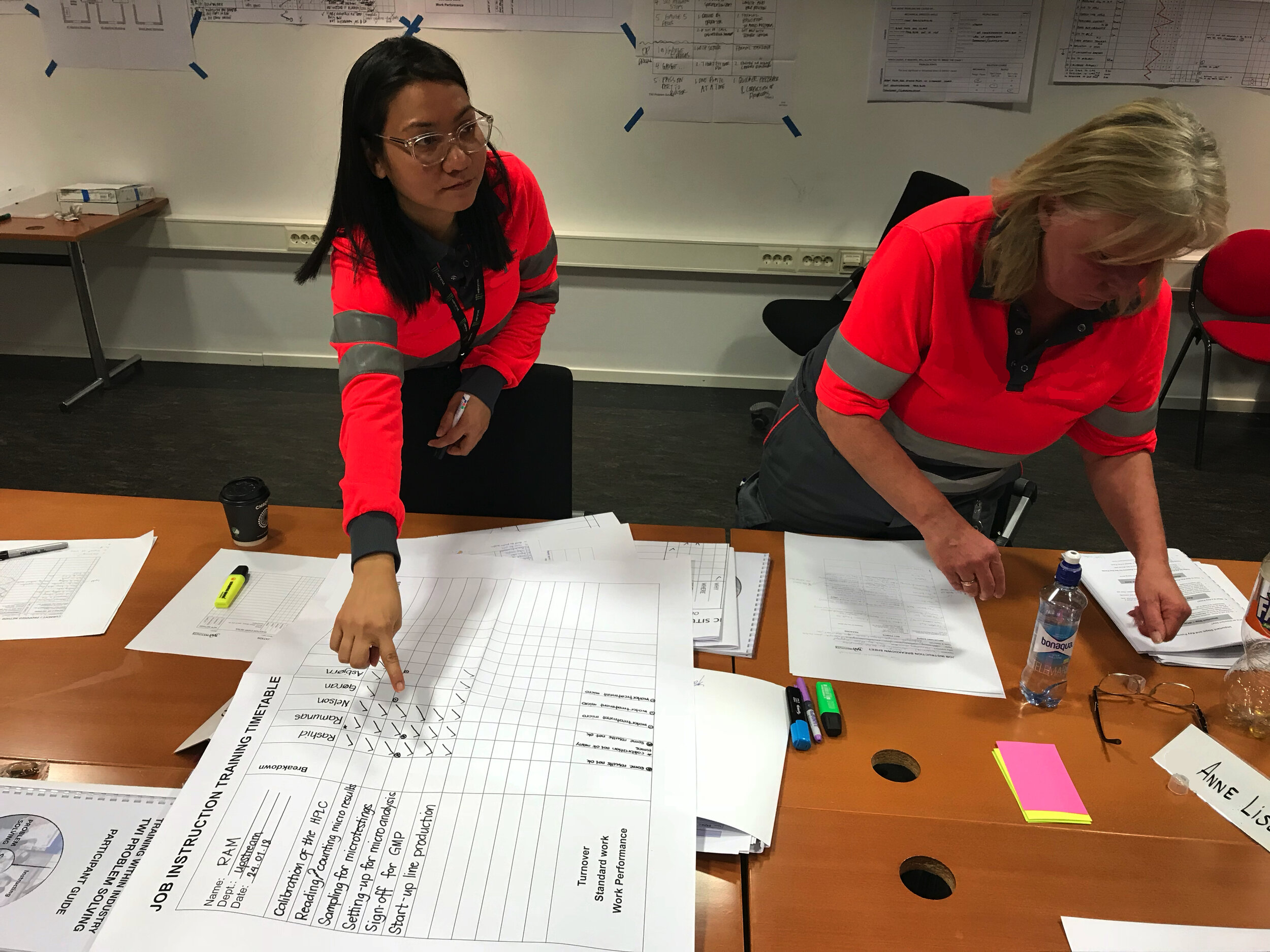

Like all TWI skills, TWI Problem Solving is based on a 4 Step pattern that is meant to be applied & repeated frequently to build effective skills and establish new habits.

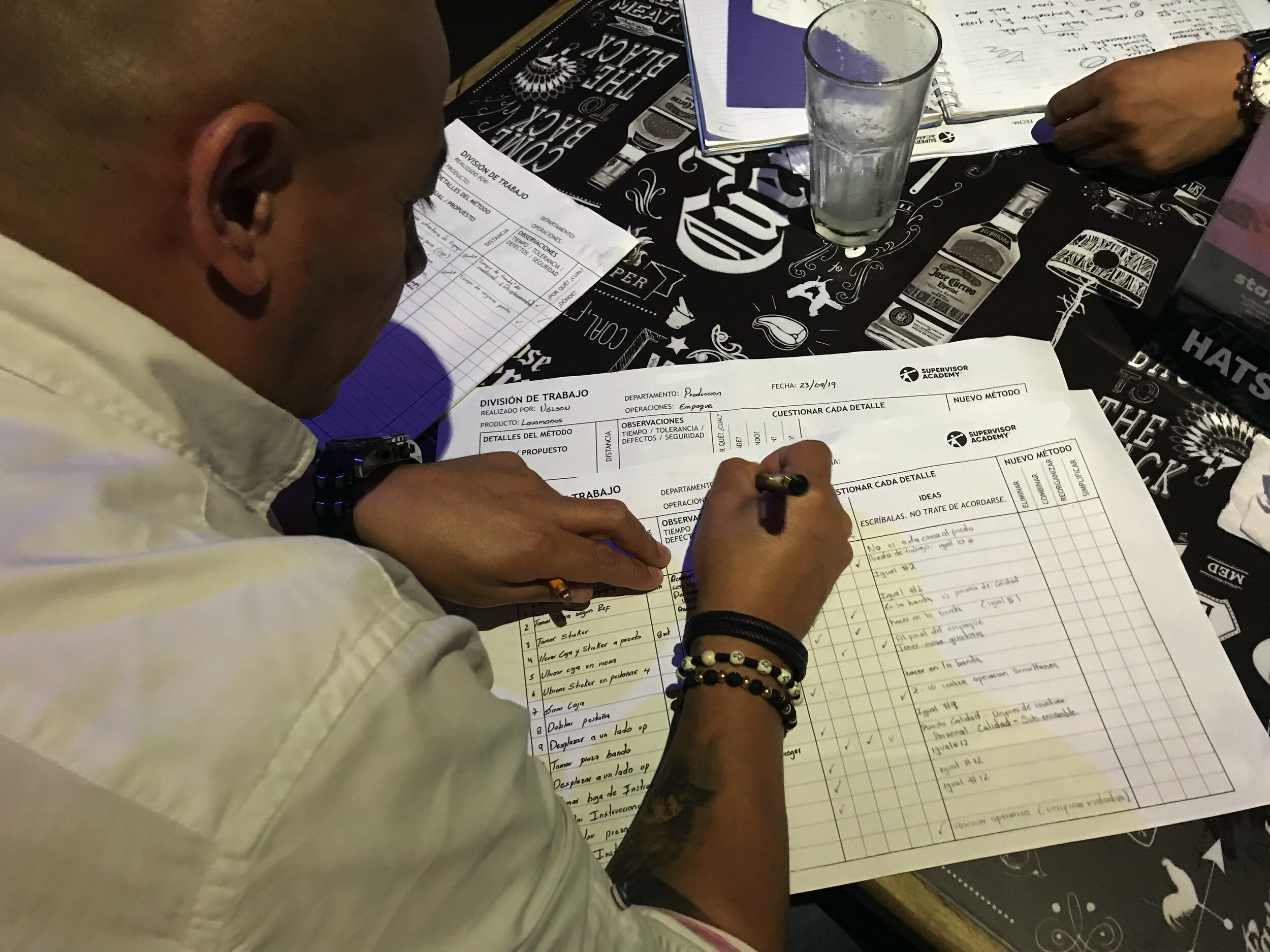

TWI Problem Solving unifies the skills of TWI Job Methods, TWI Job Instruction and TWI Job Relations into one simple, coherent framework. This means it rebalances the focus of problem solving, exploring in-depth people-related causes, not just process. It is therefore more effective and generates more sustainable solutions than other problem-solving frameworks which predominantly focus on technical aspects of the work.

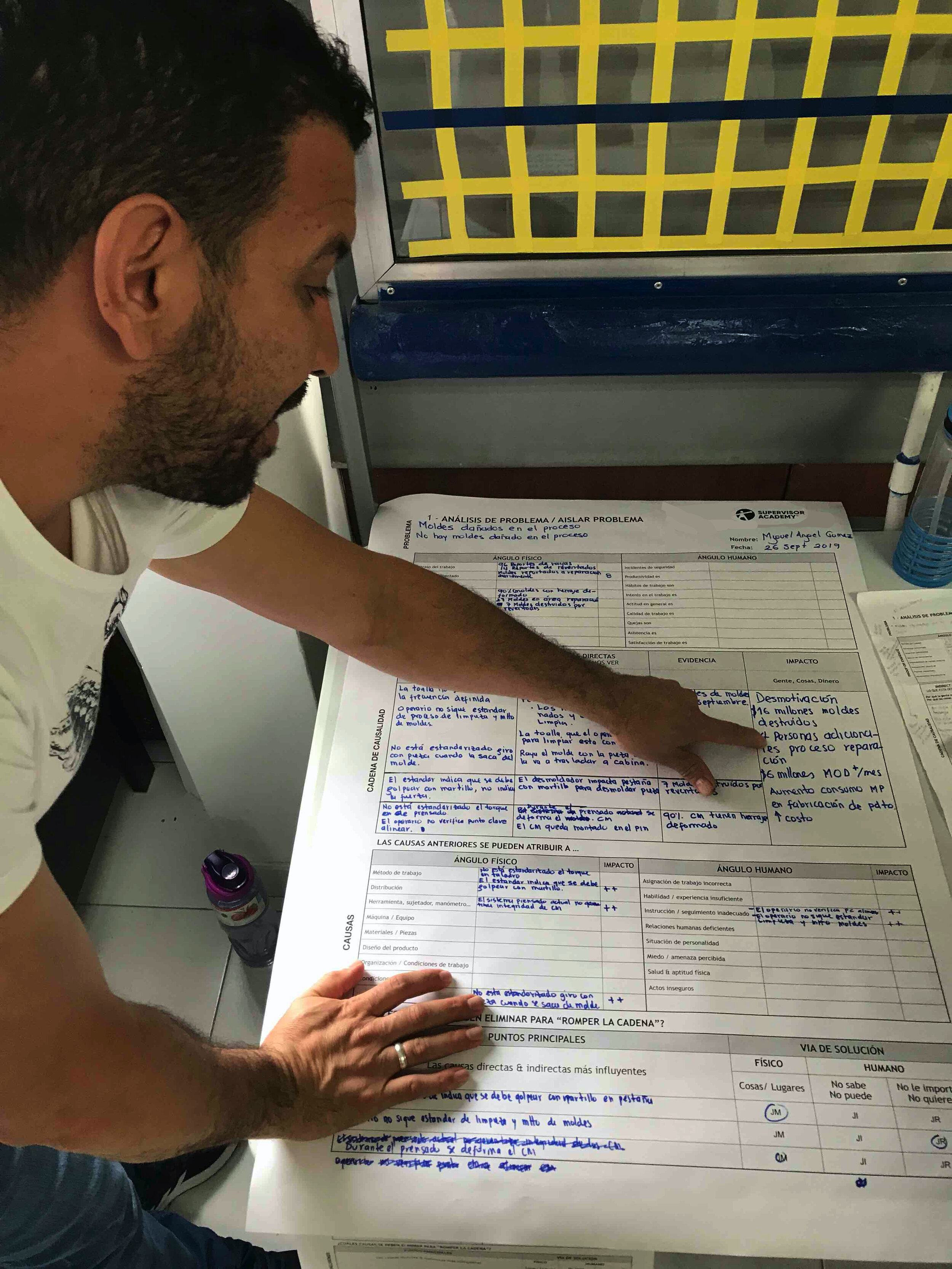

Following a carefully scripted questioning pattern, supervisors learn how to reveal the true causes of operations problems. Based on this analysis, they learn how to formulate effective solutions, that generate rapid, sustainable improvements in operating results.