FIXING QUALITY PROBLEMS FOR GOOD

TOTAL PRODUCTIVE MAINTENANCE

CASE STUDIES ON MACHINE PROBLEM SOLVING IN ACTION

Machine maintenance plays a key role in product quality. Inadequate machine settings, failing components, moving sensors or faulty adjustments are all major contributors to the Cost of Poor Quality in most factories.

“Less visible but even more important is what happens after the initial fix.”

Quickly detecting and fixing problems causing defects should therefore be a top priority in the collaboration of production supervisors with their maintenance technicians.

Less visible perhaps then the initial fix (containment or countermeasure) but, arguably even more important, is what happens next. How does the knowledge we have just gained find its way into the collective know-how of our line and maintenance teams? How do we ensure the problem is spotted and fixed faster the next time it occurs? How could we even prevent this problem from recurring?

Most maintenance departments are not very good at this. The good news is: it can be easily learned and is worth the effort. Investing in this kind of preventive capability saves a lot of money and time.

The other good news is: it does not have to be complicated. In fact, it pays to keep it simple, as this case-study illustrates…

Step 1: IDENTIFY PROBLEM POINT

Spot welding head No.3 was producing poor quality (uneven & low penetration) welds. The pneumatic cylinder that closed the weld tips was not generating enough pressure for a good weld.

STEP 2: CONTAIN THE PROBLEM

The faulty cylinder was replaced with a new one.

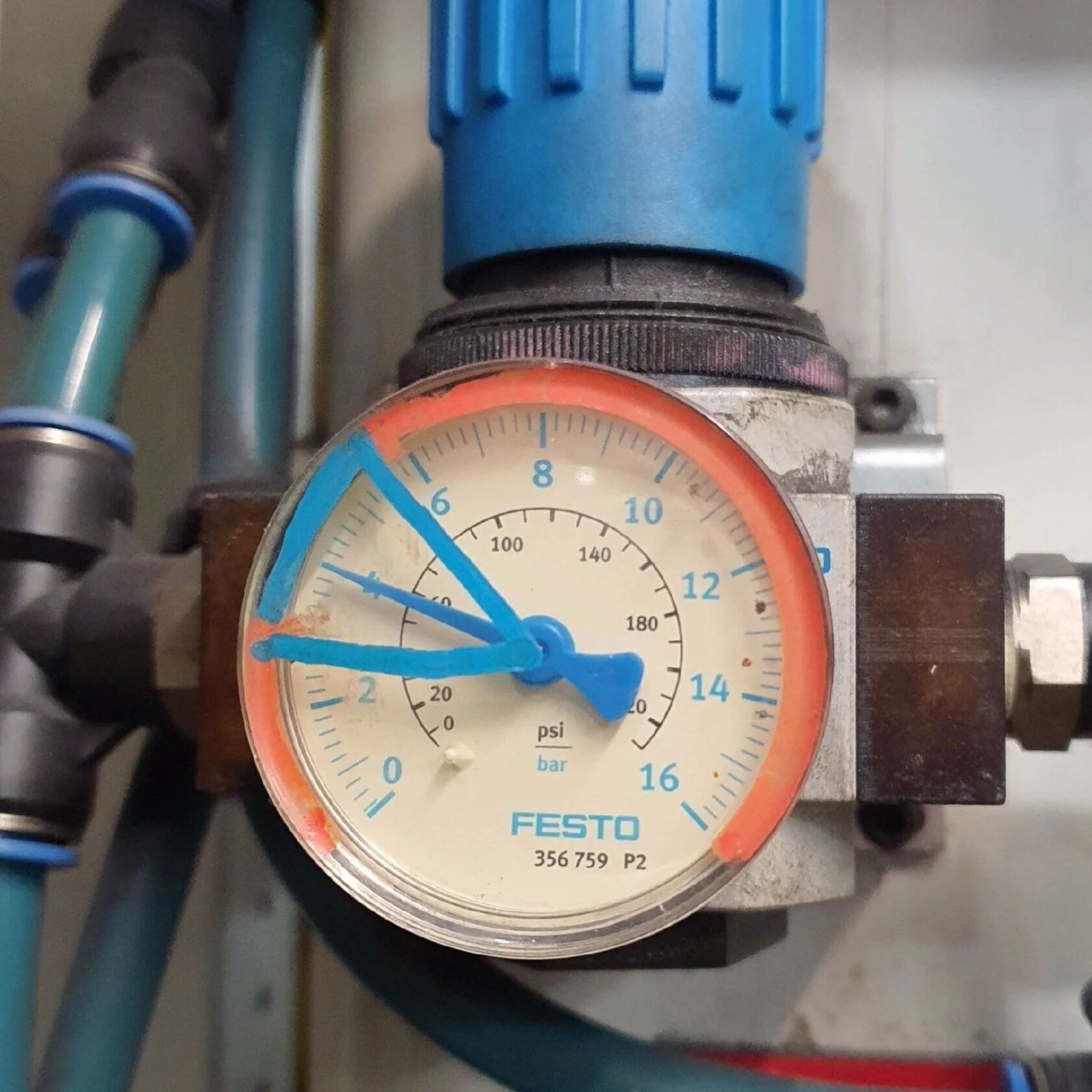

Step 3: Develop Countermeasure

With the cylinder replaced, weld pressures were reset and confirmed.

Rapid cylinder pressure vs weld quality experiments were conducted to quantify pressure thresholds

and a visual indication of the standard acceptable pressure range marked on the cylinder air-supply gauge.

Step 4: Prevent Recurrence

With the root cause of the cylinder failure likely to be wear & tear, an inspection regime was required to detect any future failures early.

The machine’s 6-monthly Preventive Maintenance schedule was updated to include a weld cylinder pressure test. Failing cylinders will be detected before weld quality is adversely effected and the cylinder changed a part of the PM reaction plans.

This Machine Problem Solving case study is based on our hands-on training and coaching sessions with Supervisor Academy clients engaged in Total Productive Maintenance (TPM) efforts. It was written by Paul Everitt & Denis Becker